|

|

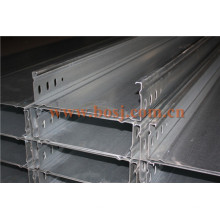

| Material of the profile

|

steel sheets for cold bending according to EN 10346 or equivalent requirements, steel grades to (at least) S450 GD, or other grade of steel with equivalent yield strength, with metal coating from Z100 to (at least) Z350

|

| Thickness range

|

1.5-3.0mm

|

| Maximum production speed

|

not less than 10 meters per minute (for non-perforated profiles, excluding cutting)

|

| Main motor power

|

15kw, AC motor, motor inside of main machine (Brand: Guomao of China)

|

| Adjust flange and width motor

|

1.5KW x3 motor inside of main machine (Brand: Guomao of China)

|

| Machine Voltage, Frequency, Phase

|

440 V, 60 Hz, 3Phase

|

| Roll station

|

20 stations

|

| Roller material

|

ASTM52100 chrome plated surface with hardness 58-62 degree ,CNC,

|

| Shaft diameter

|

¢76mm material: SAE1045 with quenching and tempering

|

| Transmission

|

by chain, one inch, double line

|

| Quantity

|

1

|

Tecnologia detalhada

Tecnologia detalhada

produtos relacionados

produtos relacionados

Tecnologia detalhada

Tecnologia detalhada

produtos relacionados

produtos relacionados